Compressed Air Conditioning-->Chemical Dryers --> With Heat Regeneration

With Heat Regeneration - ZERO PURGE - Chemical Dryers

This type of dryers, which basically work on the PSA principle, consist of adsorption material filled into two separate chambers. The humid air coming from the compressor is directed to one of the chambers and the moisture in the air is retained by the desiccant as a result of its contact with the adsorption material. Since this chamber in use will reach saturation after a while, the compressed air is directed to the other chamber and the saturated bed enters the regeneration process. While partially dried air is used during regeneration in air regeneration dryers, compressed air loss can be reduced to zero since heaters and atmospheric air are used in heat regeneration - zeropurge dryers.

In dryers with zero air loss heaters, the regeneration period begins when the pressure in the chamber is reduced to zero by opening the exhaust valve. Then, atmospheric air flow is provided into the chamber by a blower or vacuum pump and the heaters are activated simultaneously. By increasing the temperature in the chamber to 150℃, the water held by the adsorption material is quickly evaporated and discharged to the atmosphere through the exhaust valve. Then, the heaters are deactivated and atmospheric air flow into the chamber is continued and the bed is cooled. The temperature of the ambient air is very important for the cooling process to be efficient. In environments with high ambient temperature and high relative humidity, special cooling systems called loop-cooling must be used.

NONE

WEATHER

LOSS !

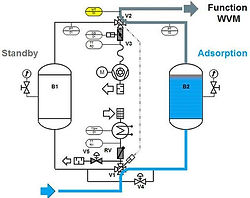

Chamber B2:

Compressed Air Drying Phase

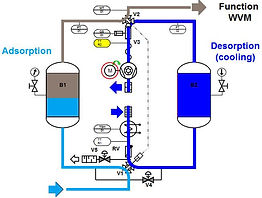

Chamber B2:

Regeneration Heating Phase

Chamber B2:

Regeneration Cooling Phase